CALIBRATION AND SERVICES

CRITICAM provides a complete after-sales package deal by offering comprehensive preventive and maintenance service contracts & solutions for Philips Patient Monitoring Systems and other medical equipment to improve equipment efficiency and response time.

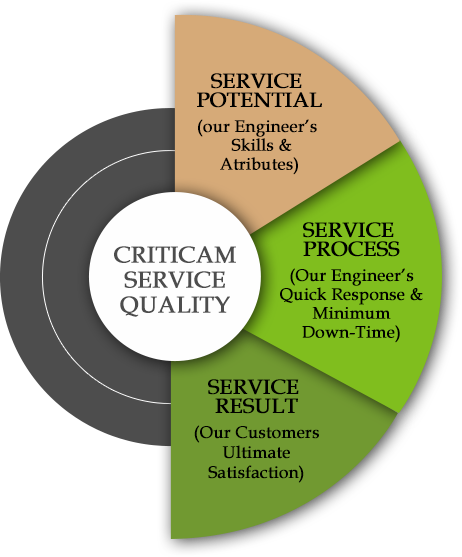

Maintenance and servicing of equipment is carried out by a team of highly qualified and trained engineers who provide effective service in the minimum down time along with supplying the parts and accessories for the equipment. With a Management team that has more than two decades of highly skilled experience, CRITICAM has consistently been at par excellence in servicing of medical equipment which is the result of constant training of our application specialists and engineers.

We at CRITICAM , believe in transforming healthcare in every direction with exceptional technology & extraordinary service. We are “Your Trusted Healthcare Service Partner”.

CRITICAM’s total Calibration Management Solution (CMS) offers a one stop service for testing, measuring and calibrating all Electro Medical Equipment. We perform a range of calibration services for electro medical equipment such as defibrillators, monitors, ventilators, cautery machines, syringe / infusion pumps, BP apparatus etc. A team of dedicated biomedical engineers and customer service professionals provide both experience and expertise in maintaining equipment at peak performance, with unrivalled commitment to customer service.

CRITICAM’s Calibration Management Solution (CMS) ensures consistency through step-by-step testing procedures and offers the following value-added services :

- Dedicated staff of highly experienced biomedical engineers

- Capability and mobility to perform onsite calibration services

- Customised testing regimes to meet the specific calibration and testing requirements

- Commitment to the best industry practice in the test and calibration of electro medical equipment

- Establishment of Quality Control (QC) & Quality Assurance (QA) protocols for medical technology and maintenance of the data secured and updated.

- Complete performance assurance and electrical safety testing

- Periodic review of historic calibration & maintenance data to evaluate appropriateness